BC Hydro Bridge River Penstock Leak Detection System

Penstock Leak Detection System

Cascadia Instrumentation Inc., distributor, and Rittmeyer AG, Switzerland, manufacturer, provided a complete Penstock Leak Detection System (PLDS) for each of four penstocks at the Bridge River 1 Hydroelectric Plant near Lillooet, BC Canada.

FMI was the prime contractor responsible for the installation of the entire Penstock Leak Detection System including:

- Drilling, tapping and installing the sensors in the penstocks with the technical support of a Rittmeyer factory trained field supervisor.

- Installing the cabinets at the PIV and TIV areas

- Installing cable trays and cables from the penstock sensors to the cabinets

- Terminating and testing cables

- Providing a Safety CSO for the entire project

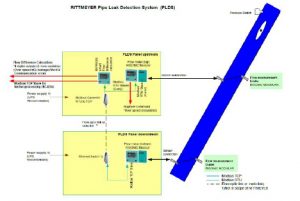

The PLDS monitors the water flow through the Penstock with two 8 path Rittmeyer Modular Meters; the upper one near the Penstock Inlet Valve (PIV), the lower one near the Turbine Inlet valve (TIV). The system only monitors the penstocks between the two meters.

Meters; the upper one near the Penstock Inlet Valve (PIV), the lower one near the Turbine Inlet valve (TIV). The system only monitors the penstocks between the two meters.

The Rittmeyer Leak Detection System provides three levels of protection:

- Low level leak detection, so small leaks can be identified and corrective action can be taken before they become a problem

- Overspeed automatic shutdown of the penstock water flow from a larger crack or break in the penstock

- Catastrophic automatic shutdown of the penstock water flow from a complete penstock failure, from a break caused by an earthquake or other such natural calamity

The Rittmeyer Leak Detection System is normally integrated into the customer’s SCADA system via the Siemans OP-77 control panel and the Rittmeyer Riflex specially programmed for the system. The top and bottom meter sections are in communication via fiber optic cable, supplied and installed by BC Hydro. An optional backup system consisting of a radio link is available. Control parameters were worked out with BC Hydro site personnel when the system was commissioned. The PLDS needs to “learn” the hydraulic characteristics of the penstock flows and get it set up for both the Leak, Over Speed and Catastrophic Control programs.

The Risonic Modular Controller, OP-77 and Riflex units were located in the top and bottom control houses in their Rittmeyer supplied cabinets. Each of the eight flowmeters has 16 transducer coax cables connected to modules in the top and bottom structures.

control houses in their Rittmeyer supplied cabinets. Each of the eight flowmeters has 16 transducer coax cables connected to modules in the top and bottom structures.

The RISONIC Modular Flowmeter System provides up to a total of twenty (20) acoustic paths in either parallel or crossed arrangement, depending on the system conditions and the customer accuracy requirements. Normal approach conditions of 10 diameters of straight run upstream from the metering section and 5 diameters downstream from the metering section, no entrained air and velocities greater than 1 fps provide the best accuracy and require fewer transducer paths.

All Rittmeyer meters use advanced methods of signal analysis (cross-correlation), to ensure proper signal detection. This advanced digital signal processing provides for:

- Very high resolution transit time measurement

- Safe signal detection in difficult hydraulic conditions

- Automatic gain control for received signal amplification

- Filtering of process data

- Received signal diagnostic information

- Adjustable transmitted signal – number of BURST

Turbine Efficiency Testing

Another benefit of the systems installed at Bridge River is the availability of the flow meter data for use in calculating the efficiency of the hydraulic turbines in the generating station. Knowing turbine efficiencies is valuable for dispatching units, maintenance and unit testing.

About Rittmeyer

Rittmeyer has been providing water and energy management instrumentation and controls, including flow measurement meters, for over 100 years to satisfied customers worldwide.

Rittmeyer offers its customers many benefits including:

- Worldwide customer knowledge base and system know how

- DSP signal processing for accurate flow measurement

- Open Communications Architecture for all Rittmeyer meters with the Risonic Modular

- Installation and commissioning services

- Test equipment to quickly determine meter or transducer problems, less downtime

- All meters measure flow in both directions

- No re-calibration requirement once the system is commissioned

- Transducers do not require special end connectors, lower cost and easier maintenance

- Multiple pipe flow meter integration via Risonic Modular

Established in 2000, Cascadia Instrumentation Inc. is a manufacturer’s representative and distributor of high-quality instrumentation products for the industrial and commercial sectors. We serve a wide range of industries, including Manufacturing, Water & Waste Treatment, Hydropower, District/Thermal Energy and Process industries including Pulp & Paper mills, Ore Processing and Chemical plants and Gas Processing. We have exclusive representation agreements with leading instrumentation manufacturers located in Canada, the USA and Switzerland.